Plants

Rizzi Srl / Plants

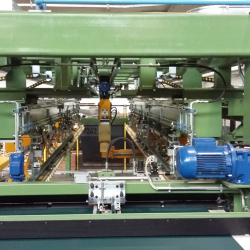

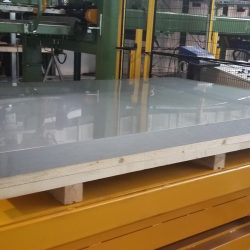

For over forty years we have been designed and manufactured hundreds of stackers, characterized by a constant increase in performance and an unchanged reliability and simplicity of management / maintenance. Rizzi has specialized over the years, managing to offer the customer the most appropriate and performing solution in relation to his production needs. From the cheapest and simple creeping stackers, to cascade type air cushion or no-stop monobox stackers; from double box non-stop stackers (suitable for noble and delicate materials such as stainless steel/aluminum), to bomb-door stackers for heavy gauge plates, the range of proposals is a definitive response to the most varied needs in the field of automatic stacking of materials in sheets, slabs or panels.

SHEETS FEATURES:

- Type: Carbon Steel and related materials / Stainless Steel / Aluminium

- Thickness range: mm. 0.2 ÷ 20.0

- Lenght: mm. 150 ÷ 20.000

- Lunghezza: mm. 150 ÷ 20.000

TYPE OF STACKERS (STOP AND NO-STOP MODE):

- Crawling

- Vacuum

- Air-cushion and rackets

- Rackets

- Bomb-door (heavy gauge)

- Magnetic

Stacking Lines For Sheets

Fill Out The Form For More Information

Discover Our Plants:

Packaging Lines For Sheet Bundles

Fill Out The Form For More Information

Discover Our Plants:

Downstream of an automatic stacking line it becomes decisive to use a series of additional automations that allow easy packaging of the bundles produced avoiding dangerous “bottlenecks”. These systems are generally composed of chain conveyors and roller conveyors dimentioned according to the customer’s logistical needs, with the possibility of 90° deviations, longitudinal and lateral translations on rails and numerous interface devices to allow the insertion of automatic packaging machines in line. The lines can handle palletized or bare material, thanks to the help of special components able to guarantee compliance with surfaces such as rubberized rollers and special chains with plastic links. RIZZI has specialized over the years in multiple automatic feeding to different possible operations on finished packages, in detail:

STACKABLE MATERIAL FEATURES:

- AUTOMATIC CROSS AND LONGITUDINAL STRAPPING

- AUTOMATIC INSERTION OF WOODS AND ANGLES

- AUTOMATIC PLASTIC FILM OR PAPER APPLICATION

These systems are fully customizable and, thanks to their modularity, it is always possible to propose the best solution to the Customer, from the baseline to the fully automated one. The line is generally composed of a downender able to singularize the slits from the unloading carousel and forward them, vertically axis, to the next roll-ways where the phases of weighing, radial strapping and centering of the slit take place. A stacking gantry with several stacking stations then provides the formation of the various bundles. The line can also be integrated with automatic evacuation solutions and subsequent packaging of the

formed bundle.

Automatic Packaging Lines For Slit-Coils

Fill Out The Form For More Information

Discover Our Plants:

Rotating chain warehouses

Fill Out The Form For More Information

Discover Our Plants:

Storage and handling are key concepts within any company that requires a complete processing cycle, from raw materials to products.

This reflection prompted Rizzi to create and refine the ROTOMAG SYSTEM over the years, a rotating chain warehouse available in several versions based on the materials to be stored, including weaving beams, rubber rolls, paper, fabric, printing cylinders and, on of plant equipment and accessories. The rational use of free spaces in height and the versatility of a product that can be modulated on the needs of the customer make our warehouses a concrete response to the need for integrated and flexible logistics, as demonstrated by the construction of hundreds of systems

Available in several versions according to the different needs and applications

- HORIZONTAL RING WAREHOUSE

- VERTICAL RING WAREHOUSE

- MIXED RING WAREHOUSE