STACKING TECHNOLOGIES TECHNOLOGIES

Welcome in

Rizzi Srl

State-of-the-art systems Made in Italy

For over 40 years leader in the field of automatic stacking and packaging of sheet metal and strips obtained from coils

The continuous refinement of the various products carried out over the years allows the company to be a point of reference both for Italian and foreign manufacturers of complete coil processing lines, and for the steelworks service centers of primary importance located in every continent.

Design & Planning

Rizzi Srl uses advanced design technologies to create customized solutions for clients.

Installation

Rizzi Srl's team of expert technicians handles the installation of various solutions.

Pre and post sales assistance

Rizzi Srl's support team is always available to assist customers before and after the sale, providing guidance and resolving any issues.

Our Clients

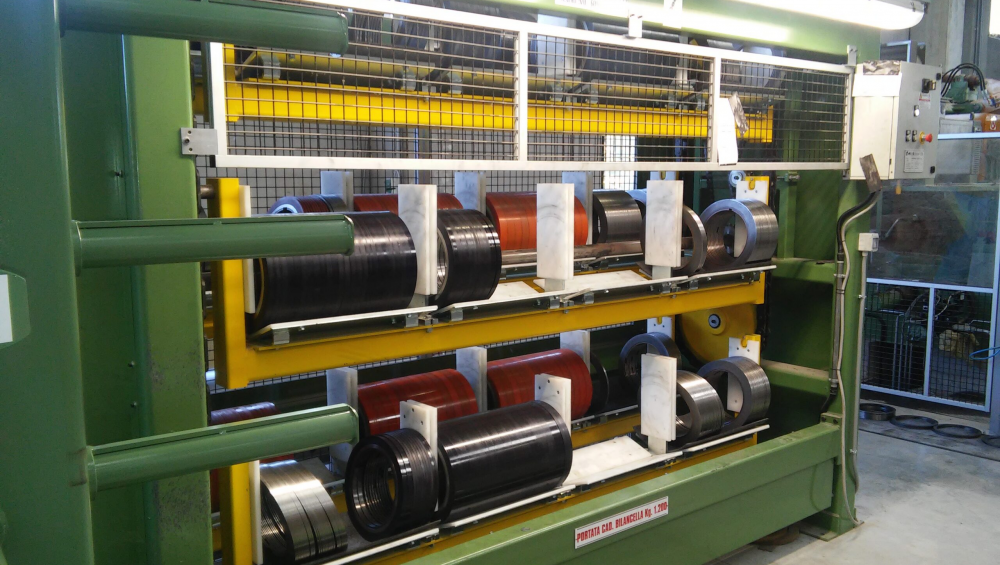

Our Productions

Rizzi srl designs, manufactures and installs complete packing and sheet metal packaging lines and special single machinery

Sheet Metal Stacking & Packaging Plants

State-of-the-art systems for the production and logistic needs of our customers. Clients. Customized performance solutions.

Single Machines

Single components of plant and machinery and stand-alone accessories for the sheet metal service centre

Rotating Chain Warehouses

Rotating chain automatic warehouses for the storage of textile beams and rolls of wrapped material for various sectors

"Tailor Made" Mechanics

Each of our custom-made systems guarantees our customers the most appropriate and performing solution in relation to the most diverse production needs.

Pre-Purchase Consulting

We evaluate your needs and recommend the best solution for your business

Design Planning

Innovative solutions designed to improve your productivity.

Productions

Handcrafted production to ensure the highest quality of our systems.

After Sales

Reliable and fast after-sales service to always support you.

Installation

Installation of systems by our specialized technicians.

Spare parts

Supply of original spare parts to ensure maximum reliability of our systems.

The entire production cycle takes place within our workshop, under the constant supervision of our technical department. Here all the processing phases take place: from cutting to carpentry, from assembly to painting.

This allows a constant control over the various processes, which translates into artisan quality: each plant is modelled according to the customer’s needs, a real

experience of “mechanical tailoring”.

No plant is the same as another: each project is the result of an in-depth study to put our customers in the position to express their logistical and production potential.